PETROMIX® - change of atomization pattern

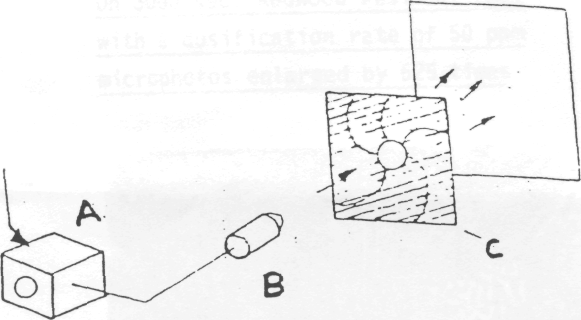

In this test, fuel of 1,000 seconds Redwood viscosity with and without additive is injected through a camera shutter onto a white paper screen:

showing clearly the change of atomization pattern ranging between

1/32" (biggest) - 0.8 microns (smallest) droplet size (total cone 0:1") - WITHOUT PETROMIX®

1/100"(biggest) - 2.0 microns (smallest) droplet size (total cone 0 : 1,25") - WITH PETROMIX®

These figures provide the explanation for combustion improvements as experienced in practice

by all PETROMIX® consumers:

The biggest droplets are considerably reduced, viz 1/3 in diameter of a circle,

which means to 1/10 by volume. Consequently, the smallest droplets have to be

increased, since the average droplet size (according to SAUTER's law) is a function

of viscosity and pressure. Since both parameters are not changed by PETROMIX®,

the smallest droplets in fact have to be bigger, thus avoiding a flash-like

initial stage of combustion as experienced in droplets' size of 0.8 microns.

Reduction of the biggest droplets on the other hand leads to reduction of soot

and coke formation; as only the biggest droplets show incomplete combustion

on account of lack of both time and sufficient oxygen during the combustion

cycle, simply blowing up to form so-called cenospheres (highly abrasive hollow balls).